are one of the most important ingredients in the food and cosmetic industry Emulsifiers .

The use of emulsifiers in various processes is inevitable.

you to the performance of these materials and the methods of making emulsions . In this article , we will introduce

Stay with us…

1# What is emulsion?

An emulsion is colloid of two or more insoluble liquids a

as the continuous phase and the other as the dispersed phase. In it, one of the liquids is known

In other words, the purpose of emulsion production is to create a stable combination of two liquids that do not normally dissolve together.

The word “emulsion” comes from “milk” in Latin, which is a natural emulsion and a mixture of water and fat.

Many of the food and cosmetics we deal with are emulsion compounds, including:

Mayonnaise, milk, many cosmetic creams

2# What is an emulsifier?

One of the most important challenges in the production of emulsions stability . is their

This stability is usually created by adding surface active compounds , which are called emulsifier compounds

Emulsifiers increase the stability of emulsions by reducing the surface tension between air-liquid and liquid-liquid.

3# Emulsion production methods

There are different methods to produce emulsion, here we mention the most common ones:

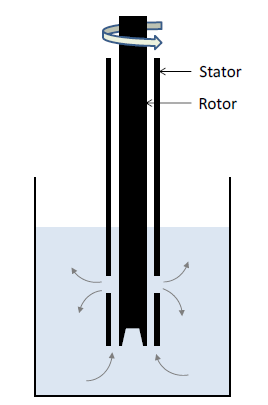

#1-3 mechanical methods of emulsion productionIn these methods, by using a stirrer and creating bubbles, the contact surface between two liquids increases and an emulsion is formed.

bubbles in smaller sizes but in high numbers. In order to produce a more stable emulsion, it is better to produce

This issue requires energy more

Usually, in such conditions, by adding emulsifiers, the necessary energy is reduced.

1) Advantages and disadvantages of the mechanical method

Advantages

- Low operating cost

- It is a very fast process so that an emulsion will be produced after a few minutes

- It can be used even in small amounts of liquid

Disadvantages

- The produced emulsion may not be uniform, which can be solved by moving the stirrer inside the tank

- The temperature rise line is always there

- We need a lot of energy to reach the smaller bubbles

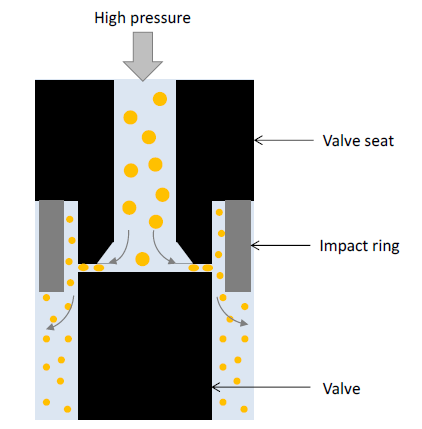

2-3 # The method of using high pressure

One of the processes used for animation in the industry is using this method.

In this method, the main equipment includes a high pressure pump and a nozzle .

When the high pressure fluid passes through these nozzles, it becomes a bubble and spreads in the continuous phase.

1) Advantages and disadvantages of high pressure method

Advantages

- They have the ability to perform the process on large and small scales

- It is possible to reach 100nm bubbles

Disadvantages

- High operating cost

- Cleaning these devices is very difficult

#3-3 Ultrasonic method

One of the methods of emulsion production is the ultrasonic method .

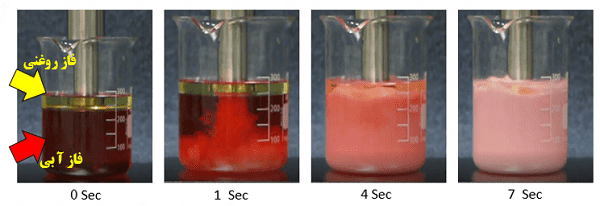

bubbles . by using sound waves and creating micro and nano In this method , two insoluble fluids form a stable emulsion phase

When the contact surface of two insoluble fluids by sound waves , is irradiated

The contact surface energy of two fluids increases and

As a result of the vibration and energy created, the dispersed phase becomes a bubble and spreads in the continuous phase.

the ultrasonic method is that by creating local oversaturation and The basis of in the continuous phase, it induces the phenomenon of nucleation in the dispersed phase

In this way, the dispersed phase becomes a bubble in the continuous phase and an emulsion is formed.

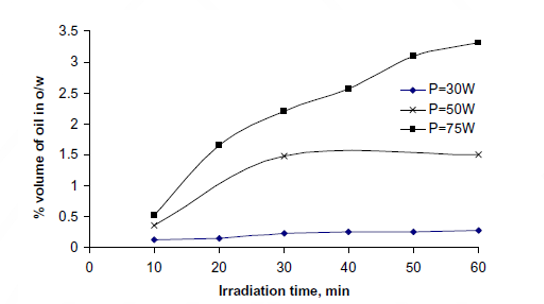

In the figure below, you can see an example of this type of emulsion created

After a short period of time, the oily phase is dispersed in the aqueous phase:

In this way, two immiscible fluids without using any surfactant or emulsifier . have formed an emulsion

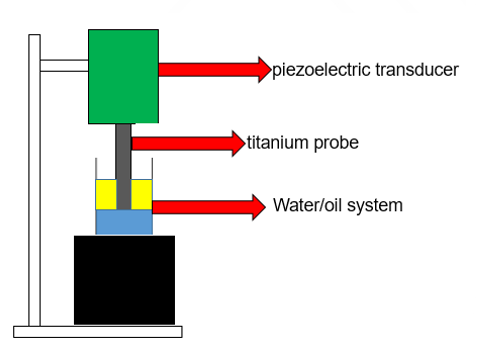

In general, in ultrasonic devices, a metal usually made of titanium is used as a probe

by a transducer containing a piezoelectric crystal It vibrates under the influence of sound waves

In such a case, the production of energy caused by the sound field causes the movement of the fluid.

One of the important parameters of these devices is the frequency of the waves, which must be set correctly.

In the figure below, you can see a diagram of ultrasonic stations.

1) Effective factors on the stability of emulsions made by ultrasonic method

Several factors are effective on the stability of the emulsion created by these devices

Among them, the most important ones are:

- duration of ultrasonic radiation

- The intensity of the radiation of sound waves

- Frequency of waves

- Properties of fluids in the system such as viscosity

- Weber dimensionless numbers (ratio of dynamic force with surface forces) and Ohnesorage (ratio of viscous forces to the geometric mean of inertial and surface forces)

With the increase in the duration of radiation and the power of the waves, the number of bubbles created increases and their size becomes smaller.

To the extent that these devices have the ability to produce bubbles in nano dimensions, in such a case nanoemulsion will be formed.

Increasing the viscosity and surface tension of the phases reduces the stability and hardening of the emulsion.

Because with the increase in viscosity, the resistance of the fluid to the entry of bubbles increases and

Also, if the surface tension is high, the tendency of the phases to each other is reduced

In this case, a harder emulsion will be formed.

The above figure shows the effect of viscosity and surface tension on the size of the bubbles.

2) advantages and disadvantages of the ultrasonic method

After examining this method and its basic parameters, we will examine its advantages and disadvantages.

Among the advantages of this method are:

- They are very simple and it is easy to carry out the emulsification process by placing the probe in a tank containing immiscible liquids.

- They are very fast so that they will be able to emulsify usually in less than a few minutes.

- It is also possible to use it for small amounts of liquid, in other words, it can be used for laboratory use.

- By adjusting different parameters, it is possible to reach the emulsion with nano-sized bubbles.

But the disadvantages of using this method are:

- For pharmaceutical, cosmetic, and food uses, there is a risk of a small amount of titanium probe precipitation.

- It is difficult to use this technique for industrial applications, in other words, to scale-up it.

- Emulsion temperature increase during the process due to high energy generation which may damage the emulsion structure.

(especially in pharmaceutical and food industries) which, of course, to solve this problem, a cooling system is used

It also has its own costs and problems

In general, a lot of research has been done on emulsion production methods without using emulsifiers

None of them has been able to eliminate the use of these materials in various industries.